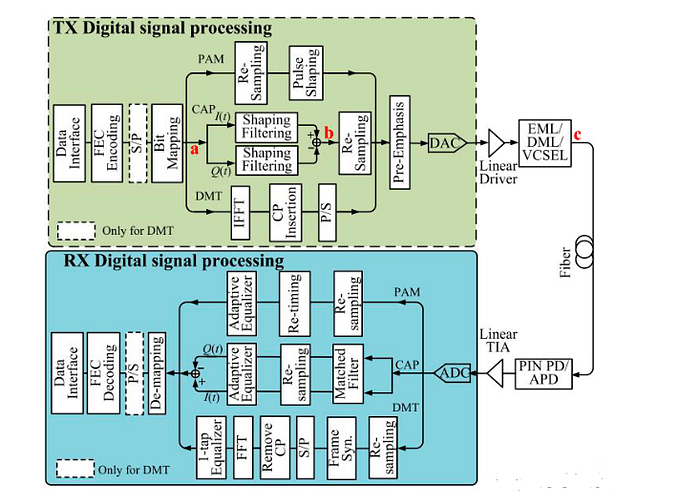

Amidst the high-speed optical module landscape, the incorporation of DSP chips for signal processing has been the norm. These chips, featuring ADC/DAC, FEC, retiming, reshaping, adaptive equalization, and more, hold immense power, yet their potency comes at the cost of significant power consumption and expenses. A typical 7nm DSP in a 400G optical module consumes around 4W, constituting 50% of the module’s power consumption.

DSP Function Block Diagram

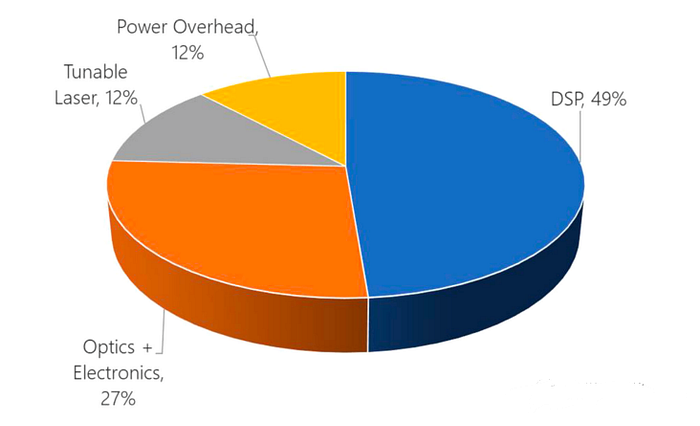

The following figure shows the power consumption breakdown of a 400G ZR optical module, with a similar scenario for an IMDD.

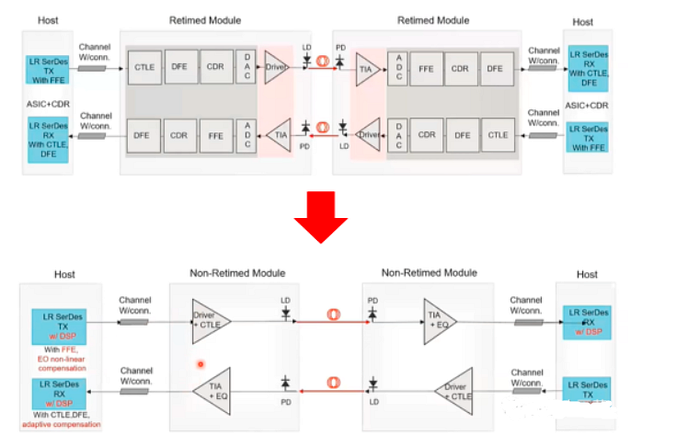

As a response to the need for efficiency, the revolutionary concept of Linear-drive technology emerged.

How can the power consumption and cost impact caused by DSP be mitigated?

By forgoing DSP within the optical module and integrating its functions into switching chips, a streamlined design emerges. The result? A compact configuration housing only driver and TIA components. Diverging from the traditional driver and TIA functions, those in the Linear Photonic Optics (LPO) architecture include CTLE and Equalization features, facilitating signal compensation. Notably, the Linear Drive concept obviates the need for retiming, eliminating non-linear processes and thus dubbed the Non-retimed module.

LPO’s merits encompass several facets:

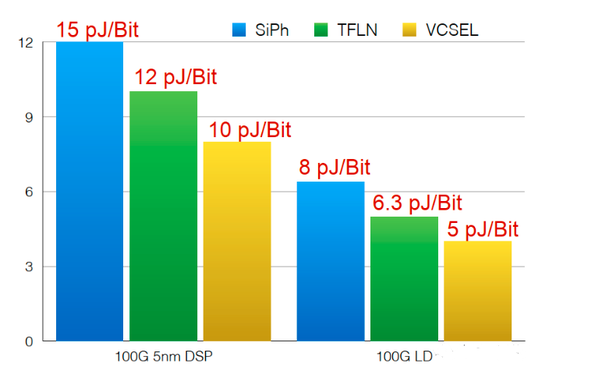

- Low Power Consumption: LPO yields a 50% reduction in power consumption compared to pluggable optical modules, aligning closely with CPO power levels.

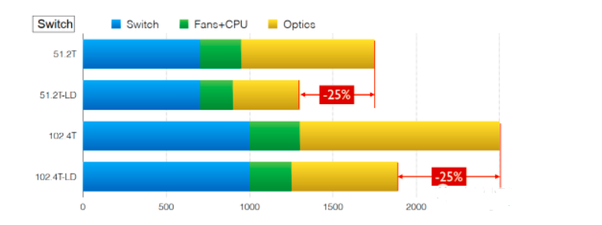

The overall power consumption of the switch system will be reduced by about 25 percent, as below.

- Low Latency: Omitting DSP significantly reduces system latency, ideal for latency-sensitive scenarios like inter-GPU communication within High-Performance Computing (HPC) centers.

- Cost Efficiency: The absence of 5nm/7nm DSP chips translates to cost savings. In an 800G module, the Bill of Materials (BOM) cost totals around $600-$700, with DSP chips accounting for approximately $50-$70. While EQ integration within Driver and TIA adds $3-$5, the total system cost reduction amounts to around 8%.

- Hot-Pluggability: LPO retains the convenience and reliability of pluggable modules, leveraging established optical module supply chains. This distinguishes LPO from CPO, which is still less widely adopted due to reliability and cost considerations.

In summary, LPO represents a novel approach with its unique advantages and ongoing challenges.

- Integration of DSP Chips: To implement LPO, there’s a need to integrate DSP chips into switches, which requires the involvement of switch chip manufacturers. The LPO concept has also stirred the competition among DSP chip manufacturers, such as Broadcom and Inphi.

- New Protocols and Testing Methods: Introducing LPO necessitates the development of new protocols and testing methods. The Optical Internetworking Forum (OIF) is currently working on defining the CEI-112G-LINEAR standard to address this need.

- Applicability and Distance: One concern is whether LPO is suitable for longer distances, potentially reaching kilometers. As DSP chips are no longer present in the module, there may be a decrease in error performance, leading to a reduction in transmission distance.

While several companies showcased their linear-drive solutions, particularly during OFC 2023, and launched LPO options post-event, the transition from technical discussions to widespread adoption is ongoing. The introduction of LPO underscores the industry’s pursuit of low-power, low-cost, high-speed optical modules.